METHOD for ADAPTIVE PROGRAMS

It's a jungle out there!

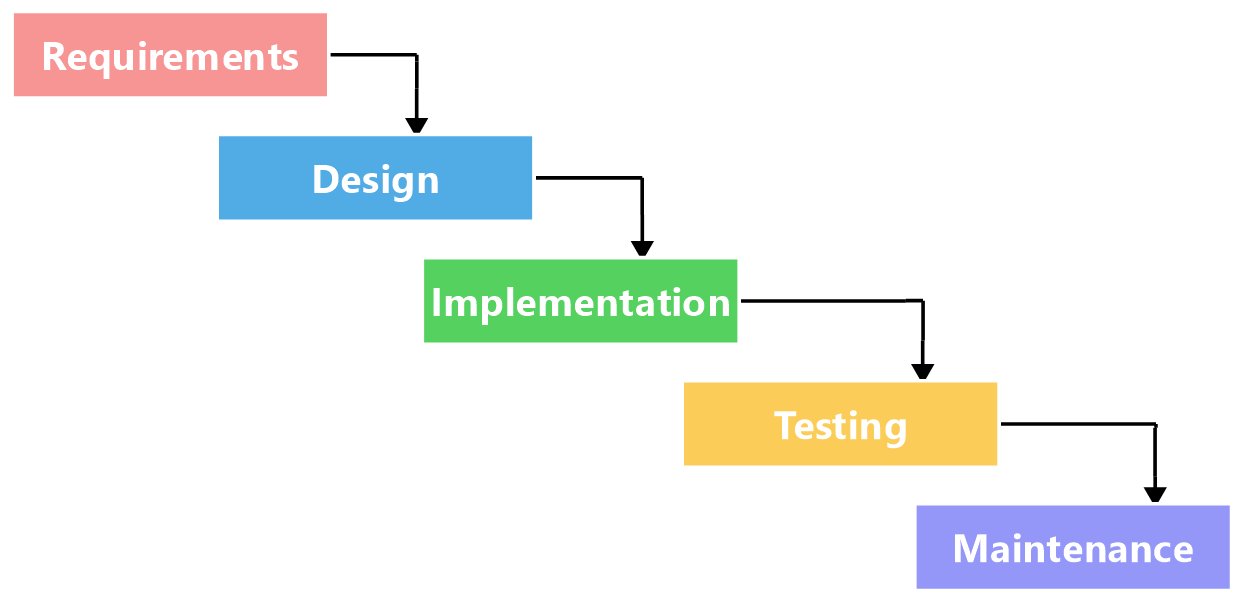

Introducing agility into your projects does not mean replacing your current processes. Agile project management is a new and better way to handle the old problem of “I will know it when I see it” associated with defining project deliverables. You tailor the traditional approach to project management with an approach that meets the agile needs of the project. More...

.jpg?width=1198&height=952&name=w3%20(1).jpg)

Six Sigma vs Lean Six Sigma

In a nutshell, Lean methodology aims at waste reduction in process, while six sigma aims at reduction of process variation. However, both approaches go hand in hand to realize the full potential for process improvements. An integrated approach of lean six sigma helps improving process efficiency, optimizing resources, and increasing customer satisfaction while improving profits and curtailing cost. More...

Poka-yoke

a Japanese term that means "mistake-proofing" or "inadvertent error prevention" for us it's simply an error proofing methodology to ensure past mistakes are not repeated. More...